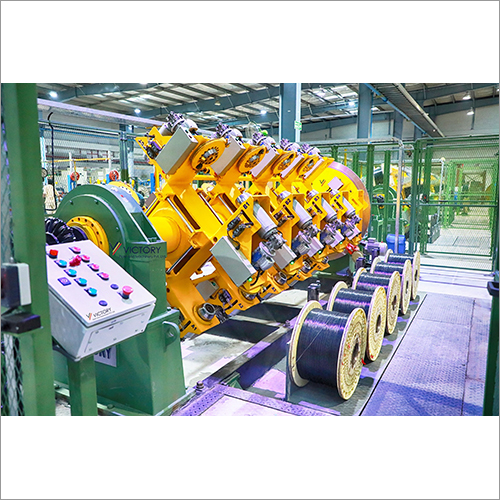

Stranding Machine With Auto Batch Loading

Product Details:

- Product Type Stranding Machine With Auto Batch Loading

- General Use High-efficiency stranding of wires and cables in industrial manufacturing environments

- Material Heavy-duty steel body with reinforced structural components

- Capacity Batch loading up to 12 spools per cycle

- Weight (kg) 16000

- Cable Type Copper, Aluminum, Steel wire, Alloy cables

- Computerized Yes

- Click to View more

X

Stranding Machine With Auto Batch Loading Price And Quantity

- 1 , , Unit

Stranding Machine With Auto Batch Loading Product Specifications

- Auto batch loading, quick changeover, precision tension control, noise-attenuating enclosure

- Yes

- Horizontal and vertical pay-off options

- High-efficiency stranding of wires and cables in industrial manufacturing environments

- Copper, Aluminum, Steel wire, Alloy cables

- 6 mm to 40 mm

- Industrial blue-gray

- Available; integrated PLC controller for process automation

- Heavy-duty steel body with reinforced structural components

- 415V, 50Hz

- 16000

- Heavy-duty multi-phase induction motor (up to 120 HP)

- Batch loading up to 12 spools per cycle

- 12000 mm x 3200 mm x 2100 mm

- Yes, with auto batch loading mechanism

- Stranding Machine With Auto Batch Loading

Stranding Machine With Auto Batch Loading Trade Information

- 1 , , Unit Per Week

- 1 Days

Product Description

Stranding Machine with Auto Batch Loading offered by our company, is widely used for providing a continuous workflow for batch loading without any dedicated labour. This machine has grooving blade which ensures the most stable and accurate grooving. This machine is very easy to install as well as simple to use. Stranding Machine with Auto Batch Loading is suitable for sealing all kind of Plastic films. This machine is user friendly and safe to operate. This machine requires very low maintenance and replacement costs. This machine is very effective and economical to use.

High-Efficiency Operation and Versatile Application

Engineered for continuous and intermittent stranding, this machine supports various cable types, sizes, and materials-including copper, aluminum, steel wire, and alloys. Its advanced drive and control systems ensure high output and flexibility required in control, power, telecom, and instrumentation cable production.

User-Centric Control and Seamless Automation

A multilingual PLC touchscreen panel, combined with computerized process automation, streamlines machine setup and supervision. The automatic batch loader and position sensors reduce manual intervention, while quick batch changeovers (under 15 minutes) maximize productivity and minimize downtime.

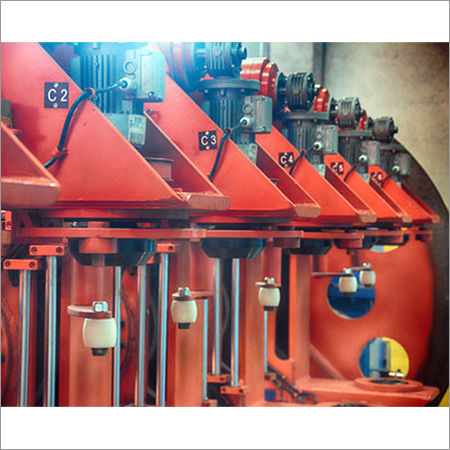

Industrial Safety and Robust Construction

Equipped with an automatic emergency stop system and interlocked access doors, operational safety is paramount. The heavy-duty steel construction, integrated noise-attenuating enclosure, and automatic central lubrication system further guarantee durability, quiet running, and long-term reliability.

FAQ's of Stranding Machine With Auto Batch Loading:

Q: How does the auto batch loading system in this stranding machine enhance efficiency?

A: The automatic batch loading mechanism, featuring an integrated loader and position sensors, enables rapid and precise spool handling for up to 12 spools per cycle. This reduces manual labor, shortens loading times, and supports quick changeovers within 15 minutes, boosting overall production efficiency.Q: What is the process for batch changeover, and how long does it take?

A: The machine's auto loader and position sensors allow seamless batch changeovers, reducing downtime between production cycles. Typically, a full batch changeover can be completed in less than 15 minutes, ensuring continuous and efficient operations.Q: When should I use the continuous versus intermittent operation mode?

A: Continuous mode is recommended for long, uninterrupted production runs, while intermittent mode is ideal for smaller batch sizes, frequent parameter changes, or specialized cable formations requiring temporary stops and starts.Q: Where is this stranding machine best utilized?

A: This machine is well-suited for industrial cable manufacturing facilities in sectors such as electrical, telecommunications, control, and instrumentation cables. Its robust design and high output make it valuable for large-scale production environments across India and internationally.Q: What types of cables and materials can this machine process?

A: The stranding machine accommodates copper, aluminum, steel wire, and various alloys. It is capable of producing both rigid and flexible strands suitable for control, power, telecom, and instrumentation cable applications with diameters ranging from 6 mm to 40 mm.Q: How does the machine maintain safety during operation?

A: Safety is ensured through automated emergency stop features, interlocked access doors that prevent accidental entry during operation, and enclosed noise-attenuating housings. All these systems help protect operators and comply with industrial safety standards.Q: What are the benefits of the PLC touchscreen and multilingual interface?

A: The intuitive PLC-controlled touchscreen interface, which supports multiple languages, simplifies machine setup and monitoring. It enables quick adjustments, real-time process automation, and easy access to diagnostics, making operation accessible to diverse user teams.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email