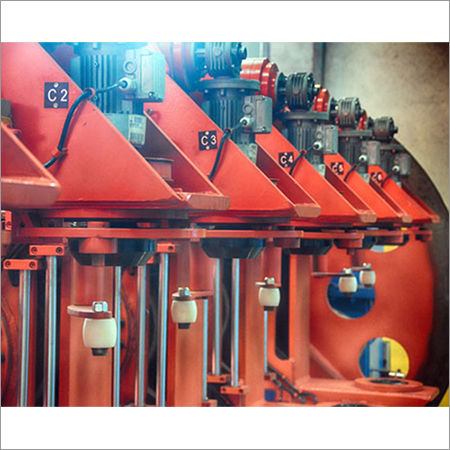

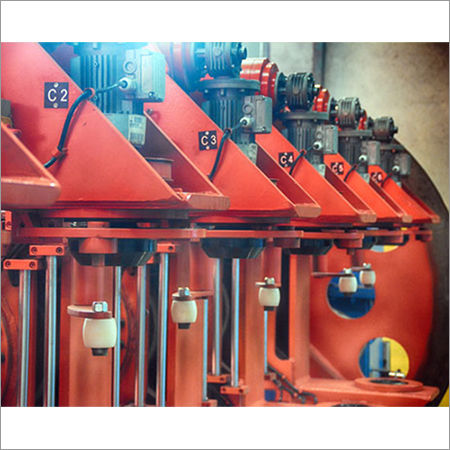

Industrial Stranding Machine

Product Details:

- Product Type Industrial Stranding Machine

- General Use Twisting or stranding of electrical wires and cables for industrial applications

- Material High-grade steel and durable metal alloys

- Capacity Up to 1200 kg/h (varies by model and configuration)

- Weight (kg) Approximately 4000 kg

- Cable Type

- Computerized Yes

- Click to View more

X

Industrial Stranding Machine Price And Quantity

- 1 Unit

Industrial Stranding Machine Product Specifications

- Industrial Blue/Grey (customization available)

- 380V / 415V, 3 Phase, 50/60 Hz

- Yes

- Yes

- Bobbin/Drum type

- High-grade steel and durable metal alloys

- 1.5 mm to 45 mm

- Approximately 4000 kg

- Up to 1200 kg/h (varies by model and configuration)

- Yes

- High production efficiency, low maintenance, precision control

- Twisting or stranding of electrical wires and cables for industrial applications

- AC/Servo Motor (varies by configuration)

- Industrial Stranding Machine

- Approx. 8500 mm x 1600 mm x 2200 mm

Industrial Stranding Machine Trade Information

- 2-3 Days

Product Description

We are committed in providing an exclusive range of Industrial Stranding Machine. It is engine with the support of talented team members and modern tools to ensure a fast speed. Apart from this, provided machine is used for stranding copper as well as steel materials. It gives a superb result of rotating and forward movement. Industrial Stranding Machine is useful for stranding of bare flexible ropes. It is easy to maintain for a longer time.

Precision Stranding for Varied Applications

Our Industrial Stranding Machine delivers outstanding precision for twisting and stranding various conductor types, including copper, aluminum, and ACSR. Its adjustable pitch and tension control mechanisms ensure reliable production quality for cables with diameters ranging from 1.5 mm to 45 mm. The system's compatibility with a wide array of wire configurations makes it a robust solution for electrical cable manufacturing across different industries.

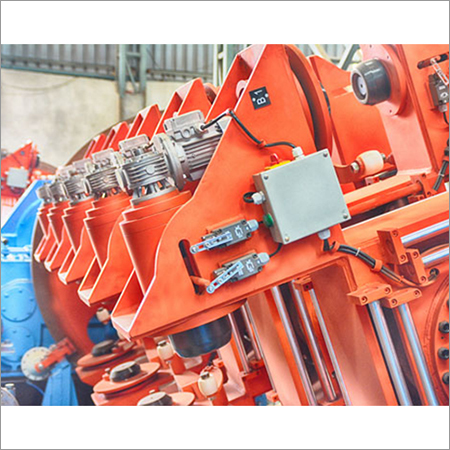

Advanced Control and User-Friendly Operation

Equipped with a highly intuitive touch screen HMI and PLC control, this stranding machine simplifies complex operations. Operators benefit from real-time process monitoring, parameter adjustment, and fault diagnostics, optimizing efficiency while reducing the learning curve. Automatic centralized lubrication and low maintenance requirements further enhance operational convenience and minimize downtime.

Superior Safety and Reliability

Safety is paramount in our design philosophy. The machine incorporates redundant emergency stop buttons, interlock guards, and overload protection to ensure operator and equipment security. Its durable construction-using high-grade steel and metal alloys-guarantees long-term reliability, even in continuous industrial use, while maintaining a noise level below 78 dB(A).

FAQ's of Industrial Stranding Machine:

Q: How does the adjustable stranding pitch benefit production processes?

A: The adjustable stranding pitch (30 mm to 500 mm) allows operators to tailor the twist length according to specific cable requirements, ensuring optimal electrical and mechanical properties for different cable types. This flexibility enhances the machine's suitability for diverse industrial applications.Q: What materials can be processed with this Industrial Stranding Machine?

A: This machine is compatible with a range of conductor materials, such as copper, aluminum, ACSR, and various other metal alloys, making it highly versatile for manufacturing different types of electrical wires and cables.Q: When is maintenance required and how is it managed?

A: Routine maintenance is streamlined by the automatic centralized lubrication system which ensures continuous lubrication of key components. The low-maintenance design further reduces manual intervention, and periodic inspections can be scheduled based on usage intensity or manufacturer recommendations.Q: Where is this machine best utilized?

A: The Industrial Stranding Machine is ideal for cable manufacturing plants, wire processing facilities, and large-scale industrial workshops involved in producing electrical cables for energy, utilities, construction, and infrastructure projects.Q: What process controls are available to ensure production quality?

A: Precision is achieved through PLC-based control, an HMI touch screen for real-time parameter adjustments, and adjustable tension control (both pneumatic and mechanical). These features enable accurate alignment and uniform stranding across various wire sizes and types.Q: How does the safety system protect operators?

A: Operator safety is assured through emergency stop functions, interlock guard systems, and overload protection mechanisms, which immediately halt operations in case of any unsafe condition or system malfunction, thereby preventing accidents and equipment damage.Q: What are the primary benefits of using this stranding machine?

A: Users gain high production efficiency (up to 1200 kg/h), reliable and precise cable stranding, wide material compatibility, reduced noise (<78 dB(A)), and straightforward operational control, making it a cost-effective and durable choice for demanding manufacturing environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email