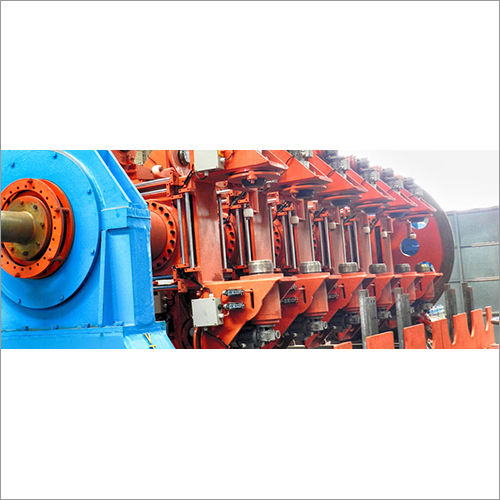

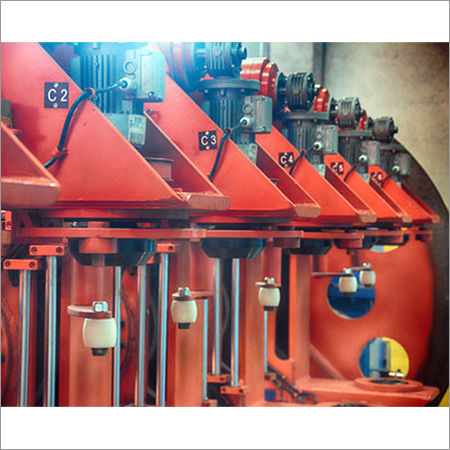

Rigid Stranding Machine With Auto Batch Loading

Product Details:

- Product Type Rigid Stranding Machine With Auto Batch Loading

- General Use Stranding and bunching of cables and conductors

- Material High-grade steel structure

- Capacity Up to 61 wires (customizable)

- Weight (kg) Approx. 15000 kg (varies with configuration)

- Cable Type Copper, Aluminium, ACSR, Power Cables

- Computerized Yes

- Click to View more

X

Rigid Stranding Machine With Auto Batch Loading Price And Quantity

- 1 Unit

Rigid Stranding Machine With Auto Batch Loading Product Specifications

- Rigid Stranding Machine With Auto Batch Loading

- Available

- Industrial Blue & Yellow (customizable)

- High-grade steel structure

- Bobbin/Basket Type

- AC motor with variable frequency drive

- Approx. 22,000 x 3000 x 2800 mm

- Approx. 15000 kg (varies with configuration)

- 380V/415V, 3 Phase, 50Hz

- Stranding and bunching of cables and conductors

- Up to 61 wires (customizable)

- 1.5 mm to 45 mm

- Auto Batch Loading, High Productivity, Safety Interlocks, Low Maintenance

- Yes

- Yes

- Copper, Aluminium, ACSR, Power Cables

Rigid Stranding Machine With Auto Batch Loading Trade Information

- 1 Days

- Asia

- All India

Product Description

Experience lofty efficiency and breathtaking productivity with our Rigid Stranding Machine With Auto Batch Loading-highly recommended for manufacturers seeking remarkable savings. This advanced machine features stranding cage sections up to 61 bobbins and boasts an impressive line speed of 60 m/min (configuration-dependent). Enjoy precise automatic tension control on each bobbin and seamless, quick loading through the automated batch system. Its touch-screen HMI, centralized lubrication, and extensive safety interlocks make it a standout choice. Built with corrosion-resistant high-grade steel, it ensures resilience and optimal performance for the stranding and bunching of a variety of cables. Get it now for elevated productivity!

Extra Features & Versatile Usage

Our Rigid Stranding Machine With Auto Batch Loading includes remarkable extras such as an intuitive touch screen HMI, centralized lubrication, automated batch loading, and highly synchronized AC drive motors. Specifically designed for the stranding and bunching of copper, aluminium, and ACSR conductors, this machine is used extensively in the manufacture of power and communication cables. Engineered with robust steel, it is often used in high-volume cable production plants to maximize throughput with minimal maintenance.

Packaging, Export Markets & Certifications

Goods transport is managed with careful loading in secure, export-grade packaging, ensuring product safety during transit and quick dispatch upon order confirmation. Our primary export markets include Asia, Africa, the Middle East, and Europe. Each machine is dispatched with all necessary certifications, meeting rigorous IEC, IS, and international standards. Our dispatching process emphasizes promptness and reliability, ensuring customers receive their machinery intact and ready for installation worldwide.

Extra Features & Versatile Usage

Our Rigid Stranding Machine With Auto Batch Loading includes remarkable extras such as an intuitive touch screen HMI, centralized lubrication, automated batch loading, and highly synchronized AC drive motors. Specifically designed for the stranding and bunching of copper, aluminium, and ACSR conductors, this machine is used extensively in the manufacture of power and communication cables. Engineered with robust steel, it is often used in high-volume cable production plants to maximize throughput with minimal maintenance.

Packaging, Export Markets & Certifications

Goods transport is managed with careful loading in secure, export-grade packaging, ensuring product safety during transit and quick dispatch upon order confirmation. Our primary export markets include Asia, Africa, the Middle East, and Europe. Each machine is dispatched with all necessary certifications, meeting rigorous IEC, IS, and international standards. Our dispatching process emphasizes promptness and reliability, ensuring customers receive their machinery intact and ready for installation worldwide.

FAQ's of Rigid Stranding Machine With Auto Batch Loading:

Q: How does the automatic batch loading system enhance production efficiency?

A: The automatic batch loading system enables swift and seamless loading of multiple bobbins, reducing downtime and manual intervention, which leads to faster production cycles and increased overall output.Q: What types of cables can be processed with the Rigid Stranding Machine?

A: This machine efficiently strands and bunches copper, aluminium, ACSR, and power cables, and accommodates a cable diameter ranging from 1.5 mm to 45 mm.Q: Where is this machine typically utilized?

A: The Rigid Stranding Machine is widely used in cable manufacturing units, particularly where high-volume production of electrical and communication cables is required.Q: What are the main benefits of the automatic tension control feature?

A: Automatic tension control ensures precise, consistent tension for each bobbin, improving product quality and reducing the occurrence of defects during the stranding or bunching process.Q: What certifications does the machine comply with?

A: Each machine is certified to conform with IEC, IS, and other international standards for cable machinery, ensuring reliability and compliance with global industry requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email