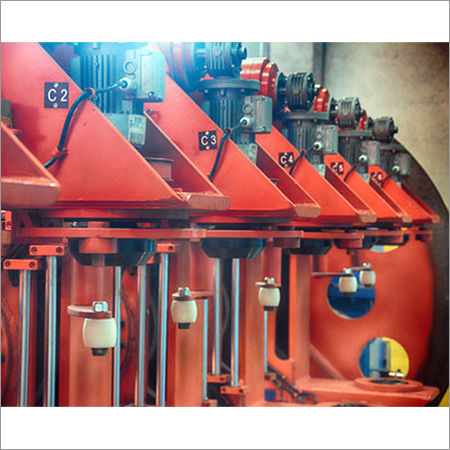

Pre Spiral Head

Product Details:

- Product Type Pre-Spiral Head

- General Use Wire and cable pre-spiraling process

- Material Heavy Duty Steel

- Capacity Up to 200 meters/min

- Weight (kg) 350

- Cable Type Multi-core & Single-core cable

- Computerized No

- Click to View more

X

Pre Spiral Head Price And Quantity

- 1 Unit

Pre Spiral Head Product Specifications

- High Precision Spiraling, Sturdy Construction, Easy Operation

- 900mm x 700mm x 1250mm

- 350

- No

- Industrial Blue

- Drum/Spool

- Wire and cable pre-spiraling process

- 380V / 415V

- Multi-core & Single-core cable

- Up to 200 meters/min

- Pre-Spiral Head

- 2mm - 16mm

- Optional

- Semi-Automatic

- Heavy Duty Steel

- 3 HP AC Motor

Pre Spiral Head Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Relying upon our huge market knowledge, we are offering a wide range of Pre Spiral Head. It is easy to place with smooth or hard both surfaces. Therefore, provided head is fitted with an improved blade for jointers. It is known for its great advance of durability and flexibility. Pre Spiral Head is basically present a shearing cut to the timber and gives a smoot cuts to enable a glass finishing. It reduces noise and provide more accurate blade changes.

High Precision Spiraling for Optimized Cable Preparation

This machine provides efficient pre-spiraling of cables with high accuracy, ensuring consistent results for wire harness and cable assembly applications. Its adjustable speed and semi-automatic operation make it suitable for both multi-core and single-core cables, delivering professional quality and reducing manual workload.

Robust Design and Reliable Protection Systems

Engineered from heavy-duty steel and powder coated for enhanced longevity, the Pre Spiral Head assures sturdy construction and industrial-grade reliability. Integrated overload and short circuit protection systems safeguard operational safety, offering peace of mind for continuous production demands.

User-Friendly and Low-Maintenance Operation

Floor-mounted and designed for easy installation, the machine features intuitive controls and optional PLC integration. Its low maintenance requirements and simple operation procedures ensure hassle-free functioning, optimizing productivity with minimal downtime.

FAQ's of Pre Spiral Head:

Q: How does the Pre Spiral Head improve wire harness manufacturing efficiency?

A: The Pre Spiral Head enhances manufacturing efficiency by automating the wire and cable pre-spiraling process, allowing for rapid processing speeds of up to 200 meters per minute and consistent, high-quality spiraling for both single-core and multi-core cables.Q: What types of cables can be processed with this machine?

A: This machine is suitable for spiraling multi-core and single-core cables with diameters ranging from 2mm to 16mm, making it versatile for various cable assembly and wire harness production requirements.Q: When should overload and short circuit protection features be utilized?

A: Overload and short circuit protection are always active during operation, automatically protecting the machine and cables from damage during high-load conditions or electrical faults, ensuring safe and uninterrupted production.Q: Where is the ideal installation environment for the Pre Spiral Head?

A: This equipment is floor-mounted and best suited for factory or industrial settings with an operating temperature range of 5C to 45C, voltage supply of 380V/415V, and sufficient space for its dimensions of 900mm x 700mm x 1250mm.Q: What maintenance is required for reliable operation?

A: The Pre Spiral Head requires minimal maintenance due to its robust design and industrial-grade components. Routine inspections and basic cleaning are typically sufficient to keep it running smoothly and efficiently.Q: How is the spiraling process controlled and monitored?

A: The machine operates in a semi-automatic mode with straightforward controls. Optional PLC integration allows for enhanced process monitoring and setup flexibility, ensuring high precision and easy operation.Q: What are the key benefits of using this machine for cable assembly?

A: Key benefits include high precision spiraling, low operating noise (<65 dB), reliable protection systems, sturdy construction, fast processing speeds, easy operation, and reduced maintenance requirements, making it a valuable asset for wire harness and cable assembly manufacturers.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email