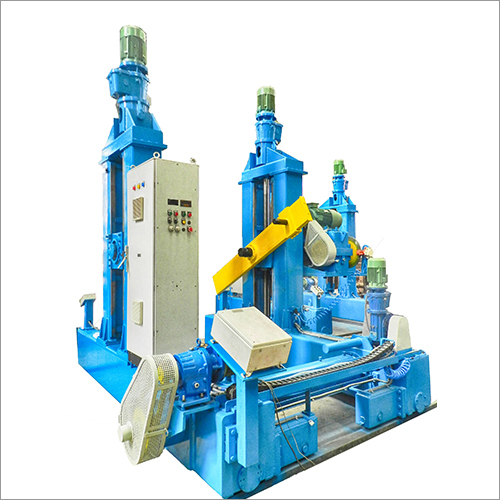

Auxiliary Machines -Take Up

Product Details:

- Noise Level <75 dB

- Motor Power 3 HP

- Diameter Drum Diameter 750 mm

- Capacity 500-1200 mm spool diameter

- Shape Rectangular Base, Cylindrical Drum

- Features Heavy-duty frame, adjustable tension, high operational stability

- Usage & Applications Winding and rewinding of cables, wires, fibers, tapes

- Click to View more

X

Auxiliary Machines -Take Up Price And Quantity

- 1 Unit

- 5°C - 45°C

- Electromagnetic Braking

- 10-120 m/min

- Digital meter counter

- Emergency Stop, Overload Protection

- Hydraulic Assisted

- PLC Controlled

- Floor Mounted

Auxiliary Machines -Take Up Product Specifications

- 380 V

- Take Up Machine

- <75 dB

- 2450mm x 1000mm x 1600mm

- Mild Steel

- Smooth

- 3 HP

- Powder Coated

- Automatic

- Drum Diameter 750 mm

- Centralized Lubrication

- Standard Atmospheric

- Standard

- Approx. 850 kg

- Electric

- Rectangular Base, Cylindrical Drum

- 500-1200 mm spool diameter

- Blue & Silver

- Winding and rewinding of cables, wires, fibers, tapes

- 3 kW

- Heavy-duty frame, adjustable tension, high operational stability

- AC Drive

- 5°C - 45°C

- Electromagnetic Braking

- 10-120 m/min

- Digital meter counter

- Emergency Stop, Overload Protection

- Hydraulic Assisted

- PLC Controlled

- Floor Mounted

Auxiliary Machines -Take Up Trade Information

- 1 Unit Per Week

- 1 Days

Product Description

Our firm has gained a dynamic position in delivering a wide arrangement of Auxiliary Machines -Take Up. It is basically utilized for handling the cargo and steering gear. It is helpful to improve the extrusion process efficiency. It is one of the best machine which ensures a great ease of operation. Auxiliary Machines -Take Up is manufactured in a modern infrastructure unit to care under the assistance of talented experts. It comes at nominal price rates.

Advanced Control and Stability

With a PLC-controlled panel and AC drive, this Take Up machine offers customizable speed and tension for varied winding applications. Heavy-duty construction and a centralized lubrication system support long-lasting reliability and minimal maintenance, ensuring consistent output and operational stability for demanding industrial tasks.

User-Friendly Operations

Loading spools is effortless thanks to the hydraulic assist system, while a digital meter counter helps monitor winding progress in real time. Easy-to-access emergency stop and overload protection guarantee user safety, making this machine a preferred solution for manufacturers focused on efficiency and security.

High Performance with Safety

Operating in ambient temperatures from 5C to 45C, the Take Up machine provides a quiet, low-noise experience (<75 dB) and withstands rigorous working conditions. Powder-coated for durability and featuring a smooth finish, its design stands out for both form and function on any production floor.

FAQ's of Auxiliary Machines -Take Up:

Q: How does the hydraulic spool loading system work on this Take Up machine?

A: The hydraulic-assisted spool loading system simplifies placing and removing spools, reducing manual effort. Operators activate hydraulic controls, allowing the unit to lift and secure spools with diameters ranging between 500 and 1200 mm onto the drum quickly and safely.Q: What safety features are incorporated into the machine?

A: Key safety features include an emergency stop button for rapid shutdown in case of emergency and overload protection to prevent mechanical or electrical faults. Together, these systems help safeguard both operators and equipment during operations.Q: When is the PLC control panel beneficial during operation?

A: The PLC control panel is especially useful during complex winding and rewinding tasks. It enables precise drum speed adjustments (from 10 to 120 m/min), tension control, and process automation, minimizing human error and enhancing productivity.Q: Where is this Auxiliary Take Up machine commonly installed in industrial settings?

A: This machine is typically floor mounted in manufacturing facilities dealing with cables, wires, fibers, and tapes. Its robust rectangular base ensures stable placement near extrusion or rewinding lines, optimizing workflow in production plants.Q: What is the process for winding cables using this machine?

A: Operators load the spool using hydraulic assistance, set desired speed on the PLC panel, and initiate winding. The AC drive smoothly powers the drum, while the digital counter tracks progress, ensuring accurate and uniform winding under controlled tension.Q: What are the primary benefits of using this machine for cable and wire handling?

A: Major benefits include automated and precise operation, reduced labor through hydraulic loading, enhanced safety, and high operational stability. Its versatility in handling various materials and spool sizes makes it suitable for exporters, manufacturers, and suppliers seeking efficiency and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email