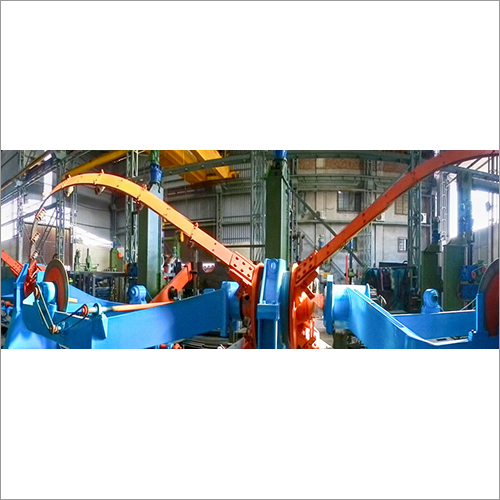

1600 MM Skip Stranding

Product Details:

- Product Type Skip Stranding Machine

- General Use Stranding of conductors and cables

- Material Mild Steel, Stainless Steel

- Capacity Up to 1600 mm bobbin

- Weight (kg) Approx. 25000 kg

- Cable Type Power Cable, AAC, ACSR, AB Cable

- Computerized Yes

- Click to View more

X

1600 MM Skip Stranding Price And Quantity

- 1 , , Unit

1600 MM Skip Stranding Product Specifications

- Mild Steel, Stainless Steel

- Skip Stranding Machine

- Yes

- 10 mm to 60 mm

- Power Cable, AAC, ACSR, AB Cable

- Yes

- Approx. 25000 kg

- Up to 1600 mm bobbin

- 415V / 50Hz

- Stranding of conductors and cables

- AC/Servo Motor

- Portal Payoff / Floor Stand

- Industrial Blue/Grey

- Robust construction, Energy efficient, Low maintenance

- Approx. 16000 mm x 4000 mm x 4000 mm

- Yes

1600 MM Skip Stranding Trade Information

- 1 , , Unit Per Week

- 1 Days

Product Description

With the aid of well-informed team, we are supplying a huge series of 1600 MM Skip Stranding. It is manufactured under the vigilance of talented team members and cutting edge tools. In addition to this, provided stranding is easy to assembled into concentric configurations. 1600 MM Skip Stranding is helpful to increase the flexibility by using end numbers of finer strands. It is suitable for stranding steel core aluminium and copper strands both purposes.

Advanced Engineering for Cable Stranding

The 1600 MM Skip Stranding Machine is designed for heavy-duty and versatile cable stranding. Featuring robust construction from high-grade mild and stainless steel, this machine ensures longevity and stability even under demanding industrial use. With an adjustable stranding pitch and a maximum rotational speed of up to 80 RPM, it meets a wide range of production requirements, handling various wire materials such as aluminum, copper, and steel core efficiently.

State-of-the-Art Controls and Safety Features

Equipped with a modern PLC system, touch screen HMI, and AC variable frequency drive, operators benefit from precise control and easy operation. Safety is prioritized through emergency stop features, comprehensive guarding, and advanced brake systems, including electromagnetic and pneumatic brakes, ensuring a safe work environment. Noise levels are controlled below 80 dB, supporting a more comfortable workplace.

Comprehensive Services and Customizable Options

To enhance user experience, the machine comes with on-site installation and operator training. Optional accessories such as taping heads, meter counters, and take-up stands further expand its functionality. Surface finishes like powder coating or painting offer added protection, and various cable and payoff types are supported, making it a well-suited solution for cable manufacturers and exporters.

FAQ's of 1600 MM Skip Stranding:

Q: How does the adjustable stranding pitch benefit cable production?

A: The adjustable stranding pitch (50 mm to 500 mm) enables operators to customize the tightness and pattern of cable strands, improving compatibility with different cable specifications and enhancing electrical performance as required by specific applications.Q: What types of wire materials and cables can this machine process?

A: This stranding machine can process aluminum (AL), copper (Cu), and steel core wires, accommodating power cables, AAC, ACSR, AB cables, and more, making it versatile for a variety of conductor and cable manufacturing needs.Q: When is on-site installation and training provided for the machine?

A: On-site installation and operator training are provided upon delivery of the machine, ensuring that your production team is fully equipped to operate and maintain the equipment efficiently from the outset.Q: Where can this stranding machine be installed and operated?

A: The machine is designed for floor-mounted installation and is suitable for manufacturing facilities, cable production plants, and export-oriented units. Its durable construction and moderate footprint make it adaptable to various industrial environments.Q: What is the process for operating the 1600 MM Skip Stranding Machine?

A: Operation involves setting up the cable materials on up to 36 bobbins, configuring the pitch via the touchscreen HMI, and managing the process through PLC controls. Safety features like emergency stops and guarding ensure smooth and secure production throughout.Q: How does the machine ensure safety during operation?

A: Safety is maintained through an emergency stop system, comprehensive machine guards, electromagnetic and pneumatic brakes, and low noise emission levels (below 80 dB), all facilitating safe day-to-day operation.Q: What are the main benefits of using this stranding machine in industrial cable production?

A: Key benefits include robust construction for longevity, energy-efficient operation, low maintenance needs, advanced computerized controls for accuracy, optimal safety features, and the ability to tailor operations to various cable and wire types.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email