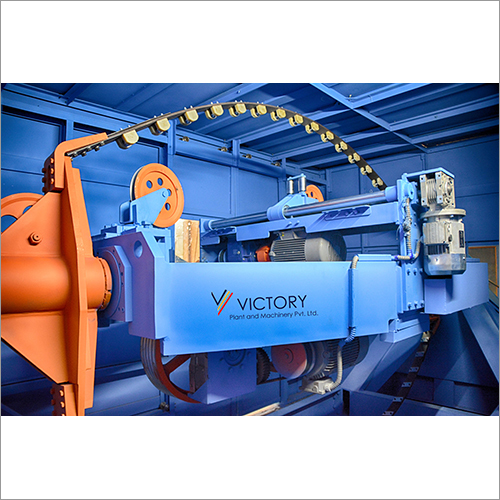

1250 Double Twist Buncher

Product Details:

- Product Type Double Twist Buncher

- General Use Twisting and bunching of wire strands for cable manufacturing

- Material Mild Steel, Stainless Steel

- Capacity Upto 250 kg/batch

- Weight (kg) Approx. 5000 kg

- Cable Type

- Computerized No

- Click to View more

X

1250 Double Twist Buncher Price And Quantity

- 1 Unit

1250 Double Twist Buncher Product Specifications

- Upto 250 kg/batch

- No

- Available

- 380V / 415V 3 Phase, 50/60Hz

- High-speed double twist technology, enhanced tension control

- Yes

- Approx. 5000 kg

- Approx. 4200 x 1600 x 1800 mm

- 1.5 mm - 12 mm (depending on model/configuration)

- Double Twist Buncher

- Mild Steel, Stainless Steel

- Twisting and bunching of wire strands for cable manufacturing

- Industrial Blue & Yellow

- AC drive motor with adjustable speed

- Drum/Spool Pay Off

1250 Double Twist Buncher Trade Information

- 1 Unit Per Month

- 2 Months

Product Description

We are successfully engaged in providing a broad variety of 1250 Double Twist Buncher. It is cherished amongst our clients for its compact design and less energy consumption. This buncher is equipped with a quality assorted of raw materials and tools. 1250 Double Twist Buncher has a maximum strand quality. It enables a high production capacity and efficient working mechanism. It is ideally for logging purpose. It is a motorized vehicle with a superb attachment of steel materials.

Advanced Double Twist Technology

Utilizing cutting-edge double twist technology, the 1250 Double Twist Buncher delivers uniform strand formation and enhanced tension control. This capability ensures cables manufactured have reliable electrical performance and durability, meeting stringent industry standards for power, control, and telecommunication applications.

Optimized for Operator Safety and Efficiency

The machine prioritizes workplace safety with emergency stop, safety guarding, and a torque limiter. The digital touch operator interface enhances ease-of-use, while the centralized automatic lubrication system minimizes maintenance downtime. Noise levels remain below 80 dB, ensuring a comfortable working environment.

Expanded Capacity and Compatibility

Accommodating up to 1250 mm bobbins and 250 kg per batch, the buncher suits both large-scale production and smaller runs. Its versatility allows it to process copper, aluminium, and other conductive wires, with cable diameters adaptable to manufacturing requirements. Integration with PLC control offers consistent batch quality and efficiency.

FAQ's of 1250 Double Twist Buncher:

Q: How does the 1250 Double Twist Buncher improve wire strand production?

A: The machine uses high-speed double twist technology, automatic tension control, and an automatic traverse system, ensuring precise twisting and bunching for uniform cable strands. Its advanced features lead to consistent output and high-quality cables suitable for various applications.Q: What safety measures are incorporated in this buncher?

A: Safety is ensured through hardware like emergency stop controls, safety guarding, and a torque limiter, minimizing operational risks. These features protect operators during high-speed production and machine maintenance.Q: When should the centralized automatic lubrication system be used?

A: The centralized automatic lubrication operates continuously during machine use, reducing wear and maintenance needs. Regular checks ensure the system runs efficiently, promoting long lifespan and optimal machine performance.Q: Where is this machine typically installed?

A: The 1250 Double Twist Buncher is commonly installed in manufacturing plants or cable production facilities, especially those dedicated to power cables, control cables, or telecommunication cables. Its robust design suits both large factories and specialized workshops.Q: What is the usual process for operating this buncher?

A: Operators load the drum or spool pay-off with wire, set desired twist pitch and cable specifications via the digital touch panel, and initiate PLC-controlled operation. The automatic traverse and take-up systems manage the feed and collection, delivering precisely twisted strands with minimal manual intervention.Q: How can manufacturers benefit from this machine's automatic features?

A: Automatic traverse, centralized lubrication, and PLC controls streamline the production process. These features reduce manual labor, increase output speed, and ensure consistency, resulting in lower operational costs and superior cable quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email